Cleaning & Serilization Instructions

Description

Surgical and dental instruments are designed to perform specific functions such as cutting, grasping, clamping, dissecting, probing, retracting, draining, aspirating, suturing, or ligating. Surgical instruments may also be used to facilitate the insertion of surgical implants.

Contraindication

Instruments should not be used for anything other than their intended use.

Warning

Devices shall be used in accordance with these instructions for use. Read all sections of this insert prior to use. Improper use of this device may cause serious injury. In addition, imporper care and maintenance of the device may render the device non-sterile prior to patient use and cause a serious injury the patient or health care provider.

Caution

- Lapromed Surgical instruments are supplied non-sterile, unless otherwise noted and must be cleaned, lubricated (if required) and sterilized prior to use according to hospital protocol and procedures outlined in this document.

- Inappropriate use of instruments may result in patient injury, damaged or broken instruments.

- Proper cleaning, handling, sterilization and standard routine maintenance (such as sharpening, lubrication if applicable) will ensure that the instruments perform as intended and will extend their useful life.

- Delicate surgical/dental instruments require special handling to prevent damaging the tips. Use caution during cleaning and sterilization.

- Do not expose instruments to phenols or iodophors.

- Do not use dry heat sterilization for aluminum or plastic made, black coated or ebonized instruments.

- Do not apply excessive stress or strain at joints; misuse will result in mis alignment or cracks at the box locks or jaws.

- Rongeurs and bone cutting forceps should only be used to cut bone, never wire or pin. Do not twist or apply excessive stress during use.

- Wear appropriate protective gloves, eyewear and clothing when handling biologically contaminated instruments.

- Instruments manufactured from different metals or with special coating, should be processed separately to avoid electrolytic action between the different metals.

- Before use, inspect the instruments for possible damage, wear or non-functioning parts. Carefully inspect the critical, inaccessible areas, joints and all movable parts.

- Damaged or defective instruments should not be used or processed.

Care And Handling

1. Precleaning:

- Keep instruments moist and do not allow blood and/or bodily fluids to dry on the instruments.

- Remove gross contaminants with steady stream of lukewarm/cool water (below 110°F/43°C). Rinse each instrument thoroughly. Do not use saline or chlorinated solutions.

- Open jaws of hinged instruments for cleaning. Give special attention to joints and serrations. Instruments having more than one part or piece must be disassembled (if possible) to expose all surfaces to the cleaning process. Retain all parts to facilitate reassembly.

- Separate sharp and delicate surgical instruments. Avoid processing instruments of different metallic composition together.

- Keep ebonized instruments separate from other stainless steel instruments to avoid scratches to and removal of the ebonized coating.

2. Rinse:

- Rinse instruments thoroughly under warm distilled or demineralized water.

3. Cleaning:

Cleaning Precautions:

- If appropriate, disassemble surgical instruments prior to cleaning and sterilization.

- Do not soak instruments in hot water, alcohol, disinfectants or antiseptics to avoid coagulation of mucus, blood or other body fluids. Do not exceed two hours soaking in any solution.

- Do not use steel wool, wire brushes, pipe cleaners or abrasive detergents to remove soil as these will damage the instrument and lead to corrosion.

- Microsurgical, plated and delicate instruments should be cleaned manually and should not be processed in an ultrasonic cleaner. Carefully protect the tips of delicate microsurgical instruments throughout the entire cleaning and sterilization process.

- To preserve the surface coating of ebonized instruments, keep ebonized instruments separate from other instruments and avoid mechanical cleaning and abrasive cleaners as these processes can scratch the surface and remove the surface coating.

- Color anodized aluminum instruments may lose their color through the use of conventional, mechanical treatment processes.

A. Manual Cleaning:

- To prevent formation of biofilm, cleaning should occur as soon as possible after instrumentation is used.

- Choose a cleaning solution appropriate for surgical/dental instruments and follow manufacturer’s instructions for use.

- The use of neutral pH detergents is recommended to avoid corrosion, pitting and breakage.

- Using a small, clean hand-held brush, remove soil from all surfaces of instrument while fully immersed in solution’s specifications forwater level.

B. Ultrasonic & Mechanical Cleaning

- For ultrasonic cleaning, follow manufacturer concentration levels of cleaning agent and temperature.

- Use an ultrasonic cleaner to remove soil from hard to reach surfaces such as grooves, crevices and moving parts after gross soil has been removed.

- Open or disassemble instruments as appropriate.

- When using mechanical washer, make sure all instruments stay properly in place and do not touch or overlap each other.

- Do not allow ebonized instruments to come in contact with each other or other instruments.

- Always follow the manufacturer’s specifications for automatic washer-ster- ilizers and use a free-rinsing, low-sudsing detergent with a neutral pH (6.0 – 8.5). Due to variations in water quality, the type of detergent and its concentration may require adjustment for optimal cleaning.

4. Rinse And Dry:

Rinse all instruments thoroughly with distilled, pyrogen free water to remove all traces of debris and cleansing agents. Make sure all internal lumens and ratchets are thoroughly rinsed. Instruments must be thoroughly dried and all residual moisture must be removed before they are stored. Use a soft, absorbent towel/cloth to dry external surfaces. Com- pressed air may be used to aid the drying process.

5. Lubricate:

The use of a water soluble instrument lubricant that is compatible with the method of sterilization to be used is recommended before instruments are sterilized.

- After thoroughly cleaning the instruments, proper application of lubricants to all joints and movable mating surfaces will keep them moving freely and aid in protecting surface from mineral deposits.

- Proper lubrication is required for all instruments, regardless of surface coatings.

- Note that ultrasonic cleaners remove all lubrication; therefore, this main- tenance procedure should be done routinely after ultrasonic cleaning and before sterilization.

- If following the lubricating procedure, do not rinse after this step.

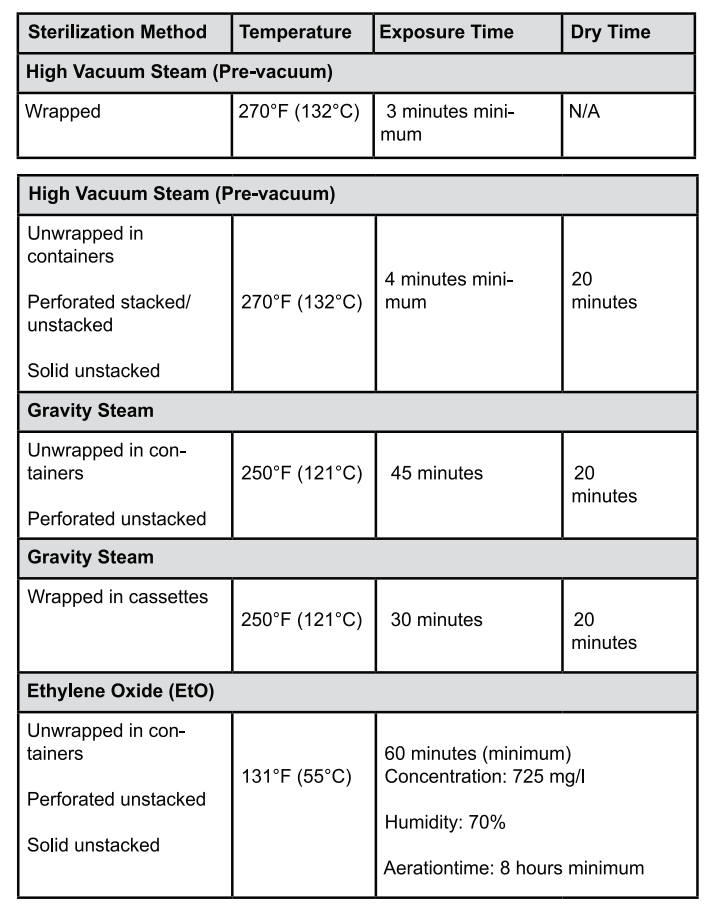

6. Sterilization:

- All devices must be processed in the completely open position (i.e. flushports, jaws, etc.) to allow sterilant contact of all surfaces.

- All devices with concave surfaces shall be configured so that water pooling does not occur

7. Storage:

After sterilization, devices must remain in sterilization packaging and be stored in a clean, dry envionment.

Returned Goods Policy & Warranty

Returned Goods Policy

1. Goods will be accepted for return for the following reasons and must be accompanied by a RGA. ,

- A. If shipment was made without Customer s authorization;

- B. If incorrect items were shipped;

- C. If defective items were shipped;

- D. If defective goods are covered by the standard warranty;

- E. If the goods were sent on evaluation basis.

2. To return goods, contact a Customer Service Representative by telephone for an RGA (Returned Goods Authorization) number. The RGA # must also be clearly indicated on the outside of the returned package.

Please have the following information:

- A. Reason you wish to return the goods;

- B. Quantity, description, product number;

- C. Date of Receipt of Order;

- D. Customer’s Purchase Order and the Carnegie Surgical invoice number;

- E. All instruments that have been used must be cleaned and sterilized prior to shipment.

3. Shipment must be returned prepaid by Customer. Freight collect shipments will not be accepted.

4. It Customer intends to return equipment ordered in error, the following restocking charges and terms will apply:

- A. 25% within 90 days from date of shipment;

- B. Goods must be returned unused, in the original carton, and in marketable condition;

- C.Refurbishing and replacement charges will be added to the restocking charges for damaged or missing items;

- D. No return after 90 days;

- E. No refund on sterile, single-use disposable products.

- F. No refund will be made on customized instruments.

Warranty

Lapromed Surgical stainless steel instruments are warranted for a period of one (1) year from the original date of purchase. Lapromed Surgical single patient use products are warranted for 90 days against defects in work-manship or materials that are discovered prior to initial use or expiration. If instruments should fail as the result of a defect in materials or workmanship, Lapromed Surgical is committed to take steps it believes are necessary to rectify the problem.

These steps may include, but are not limited to, repair, replacement or supplying an alternative instrument. This warranty does not cover general maintenance such as cleaning and sharpening services required as a result of normal use. It does not include damage that is caused by misuse, improper care, the use of improper chemicals or cleaning methods, negligence, modifica- tion or unauthorized service by non-Lapromed Surgical personnel, or normal wear. Damage to insulating coatings on electro-surgical instruments is excluded from the terms of this warranty.

The sole remedy under this warranty shall be repair or replacement as provided above at the sole discretion of Lapromed Surgical Instruments. In no event will Lapromed Surgical be liable for any damages arising out of loss of use, or any other incidental or consequential damages. The foregoing limited warranty is in lieu of any other warranty with respect to Lapromed Surgical products. Lapromed Surgical grants no other warranty, express or implied.